8

Table 1

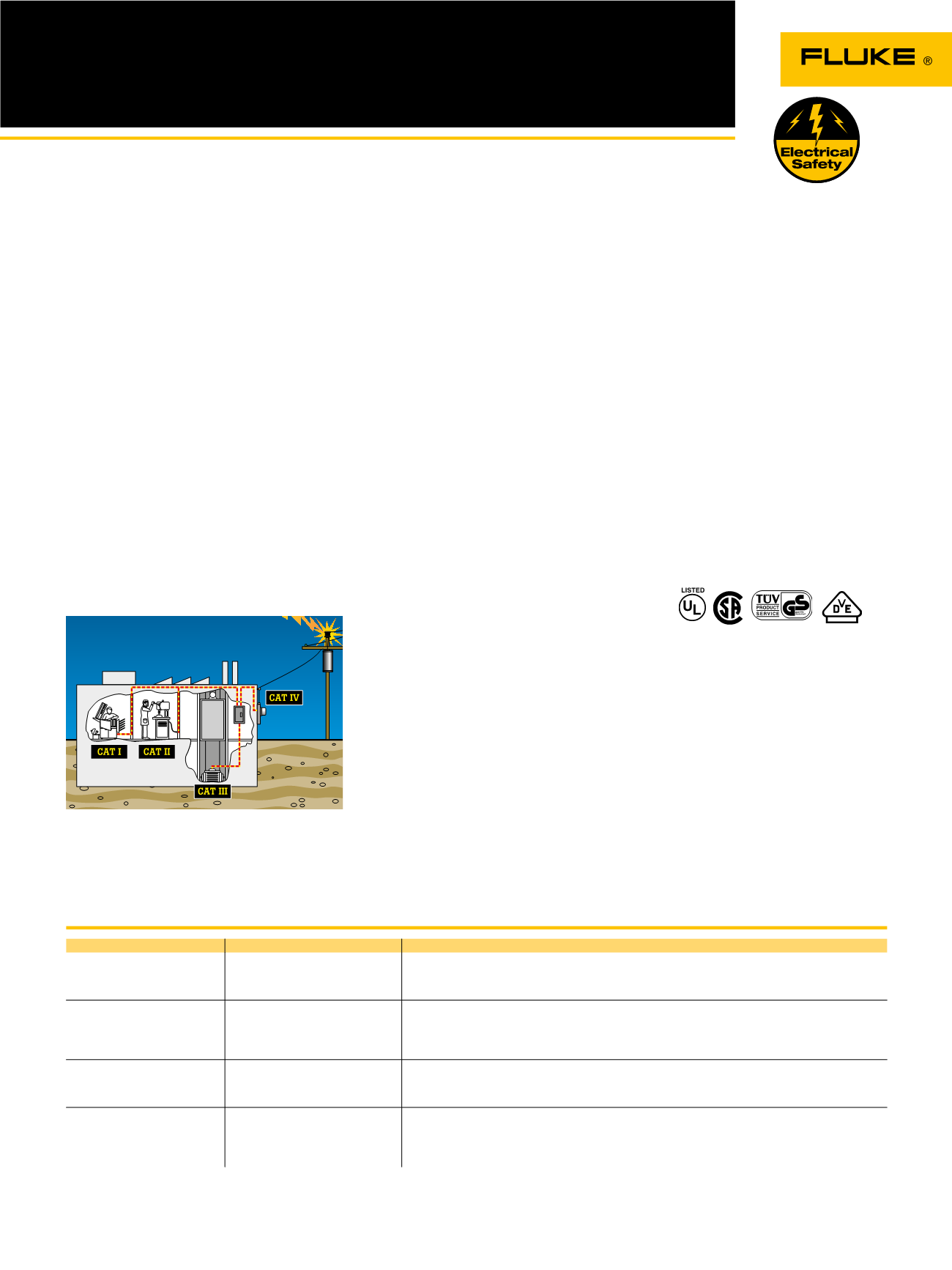

Figure 1. Understanding categories: location

Overvoltage installation categories. IEC 61010-1 applies to low-voltage (< 1000V) test equipment

Fluke: Where safety is built in

Overvoltage category

In brief

Examples

CAT IV

Three-phase at utility connection,

any outdoor conductors

• Refers to the “origin of installation”; i.e., where low-voltage connection is made to utility power.

• Electricity meters, primary overcurrent protection equipment.

• Outside and service entrance, service drop from pole to building, run between meter and panel.

• Overhead line to detached building, underground line to well pump.

CAT III

Three-phase distribution, including

single-phase commercial lighting

• Equipment in fixed installations, such as switchgear and polyphase motors.

• Bus and feeder in industrial plants.

• Feeders and short branch circuits, distribution panel devices.

• Lighting systems in larger buildings.

• Appliance outlets with short connections to service entrance.

CAT II

Single-phase receptable

connected loads

• Appliance, portable tools, and other household and similar loads.

• Outlet and long branch circuits.

• Outlets at more than 10 meters (30 feet) from CAT III source.

• Outlets at more than 20 meters (60 feet) from CAT IV source.

CAT I

Electronic

• Protected electronic equipment.

• Equipment connected to (source) circuits in which measures are taken to limit transient overvoltages

to an appropriately low level.

• Any high-voltage, low-energy source derived from a high-winding resistance transformer, such as the

high-voltage section of a copier.

As distribution systems and loads

become more complex, the possibilities

of transient overvoltages increase.

Motors, capacitors and power conversion

equipment such as variable speed drives

can be prime generators of spikes.

Lightning strikes on outdoor transmission

lines also cause extremely hazardous

high-energy transients. If you’re taking

measurements on electrical systems,

these transients are “invisible” and

largely unavoidable hazards. They occur

regularly on low-voltage power circuits,

and can reach peak values in the many

thousands of volts. To protect you against

transients, safety must be built into the

test equipment.

Who Develops Safety Standards?

The IEC (International Electrotechnical

Commission) develops international general

standards for safety of electrical equipment

for measurement, control and laboratory

use. IEC61010-1 is used as the basis for the

following national standards:

• US ANSI/ISA-S82.01-94

• Canada CAN C22.2 No.1010.1-92

• Europe EN61010-1:2001

Overvoltage Installation Categories

IEC61010-1 specifies categories of

overvoltage based on the distance the piece

of equipment is from the power source

(see Fig. 1 and Table 1) and the natural

damping of transient energy that occurs

in an electrical distribution system. Higher

categories are closer to the power source and

require more protection.

Within each installation category there are

voltage classifications. It is the combination of

installation category and voltage classification

which determines the maximum transient

withstand capability of the instrument.

IEC 61010 test procedures take into account

three main criteria: steady-state voltage,

peak impulse transient voltage and source

impedance. These three criteria together will

tell you a multimeter’s true voltage withstand

value.

Within a category, a higher working voltage

(steadystate voltage) is associated with a

higher transient, as would be expected. For

example, a CAT III 600 V meter is tested

with 6000 V transients while a CAT III 1000 V

meter is tested with 8000 V transients.

So far, so good. What is not as obvious is the

difference between the 6000 V transient for

CAT III 600 V and the 6000 V transient for

CAT II 1000 V. They are not the same. This is

where the source impedance comes in. Ohm’s

Law (Amps = Volts/Ohms) tells us that the 2 Ω

test source for CAT III has six times the current

of the 12 Ω test source for CAT II. The CAT III

600 V meter clearly offers superior transient

protection compared to the CAT II 1000 V

meter, even though its so-called “voltage

rating” could be perceived as being lower. See

Table 2.

Independent testing is the key to safety

compliance

How can you tell if you’re getting a genuine

CAT III or CAT II meter? Unfortunately it’s

not always that easy. It is possible for a

manufacturer to self-certify that its meter

is CAT II or CAT III without any independent

verification. The IEC (International

Electrotechnical Commission) develops and

proposes standards, but it is not responsible

for enforcing the standards. Look for the

symbol and listing number of an independent

testing lab such as UL, CSA, VDE, TÜV or other

recognized approval agency.

These symbols can only be used if the product

successfully completed testing to the agency’s

standard, which is based on national and

international standards. UL 3111, for example,

is based on EN61010-1. In an imperfect world,

this is the closest you can come to ensuring

that the meter you choose was actually tested

for safety.