50%

0%

100%

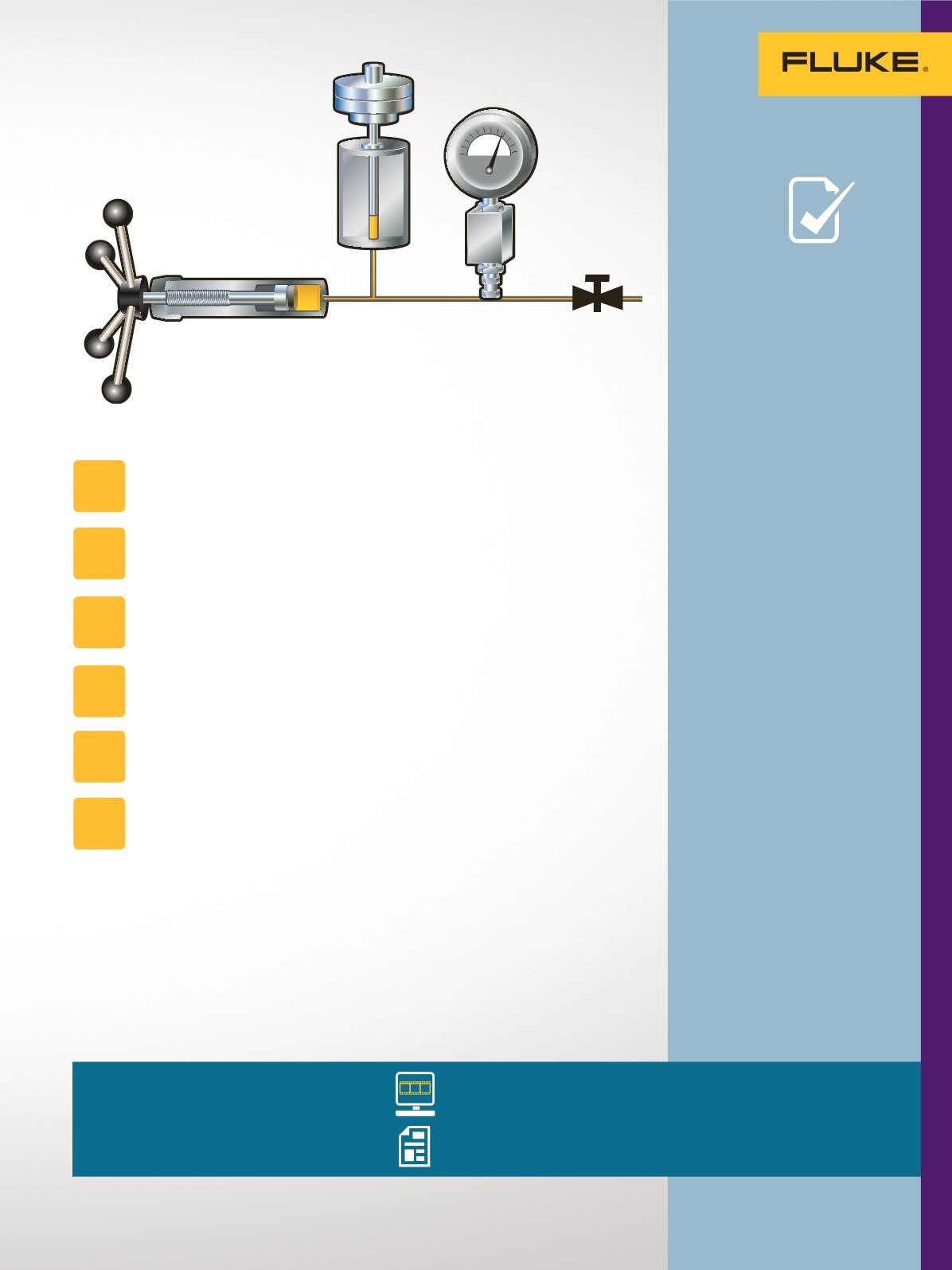

The pressure gauge should be mounted in the same orientation

(vertical or horizontal) as in the process.

Measurement points should be distributed uniformly over the

calibration range.

Calibrated weights are placed on the instrument corresponding

to the measurement points.

Pressure is added with an internal pump or screw press until the piston

holding the weights begins to float.

The piston and weight are spun by hand to minimize friction.

While the piston is floating the reading on the device under test is com-

pared to the pressure corresponding to the sum of the selected weights.

•

Deadweight tester

weights are calibrated to

match a wide range of

pressure units.

•

Local gravity often is the

largest factor affecting

accuracy. Use Fluke

PRESSCAL software to

achieve accuracy of

+/- 0.008%.

•

To increase the number of

available set points, use

incremental weight sets.

•

Forgo wrenches or PTFE

tape by using adapters to

fit multiple sizes and types

of devices with leak tight

seals to 20,000 psi.

•

Safety First! Choose fittings,

tubing and seals with

pressure ratings above the

full scale of the instrument.

•

Hydraulic systems are

preferable to gas systems

for pressures above 2000

psi due to safety and ease

of use.

•

Consider achieving

cleanliness using distilled

water as a media or use a

liquid separator from Fluke

instead of gas.

•

Lubrication can improve

performance by using oil

when it is allowed.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

5

STEP

6

To perform the test:

Additional resources

For more in depth information about

this application check out these videos

and application notes from Fluke.

Check out the 700G videos.

700G Data Sheet.

Interpreting Specifications for Process Calibrators, Application Note

TECH

TIPS

39

Pressure Applications