Pump

Close

valves

Close

valves

720TRD

RTD Probe

Fluid

stream

Fluid

stream

7.21psi

30V

24mA

MAX

V

mA

COM

F1

F2

F3

ZERO

PRESSURE

CALIBRATOR

721

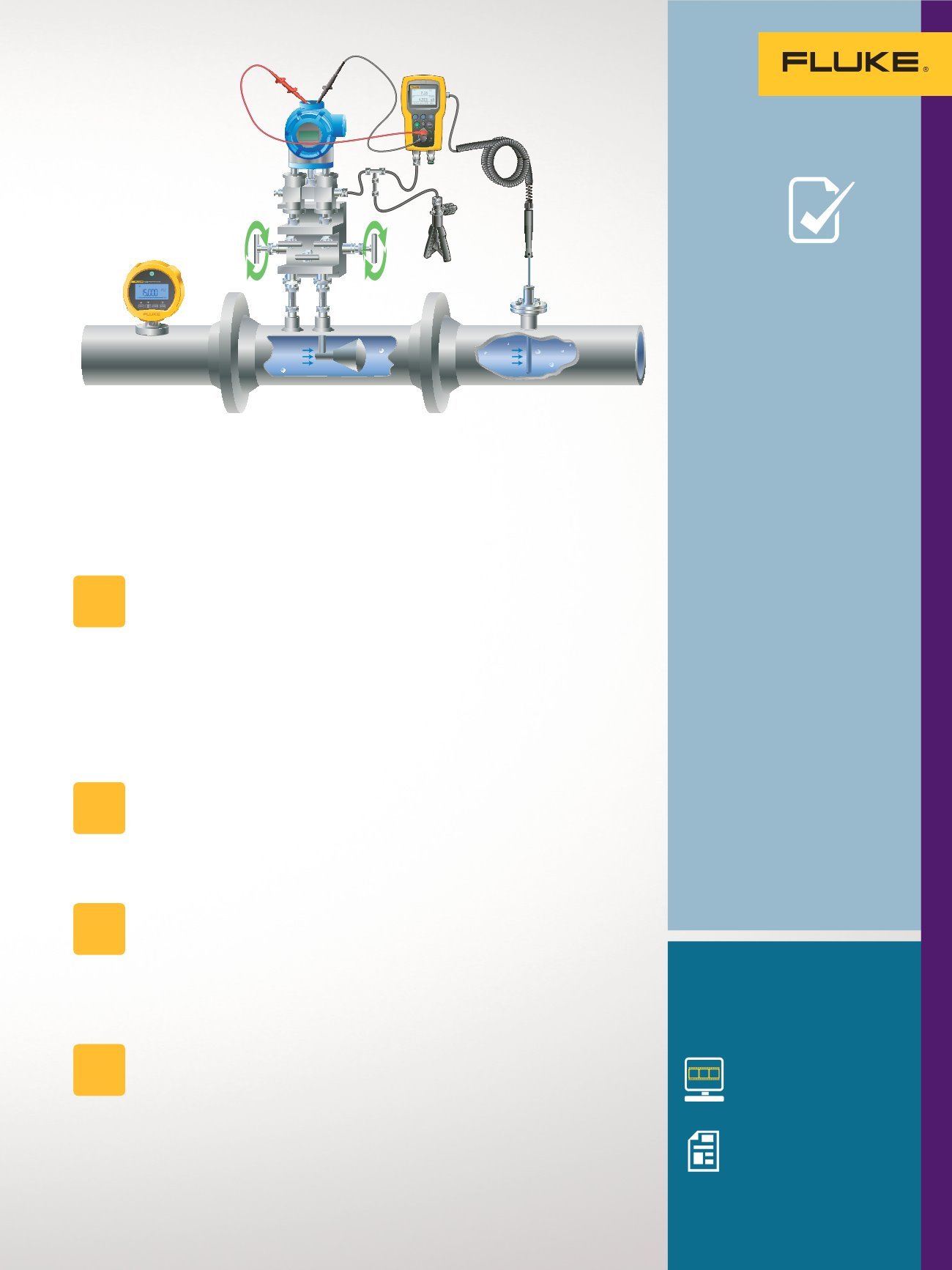

To get started, isolate the flow computer from the pipeline. It is normally in-

stalled with a 5 valve manifold. If so, closing the valves on the pipeline side

of the manifold should isolate it. Be sure to follow local policy and safety

procedures when performing this isolation step. Set the P1 sensor of the

721 to measure inH20 and the P2 sensor to measure PSI and the tempera-

ture sensor to measure degrees Celsius or Fahrenheit as needed.

Low pressure differential pressure calibration

is performed using

atmospheric pressure as a low side reference. Vent the low connection

of the flow computer or pressure transmitter and connect the high pressure

connection of the flow computer or transmitter to the low pressure port (P1)

on the calibrator.

Connect the computer (PC) to the flow computer serial or USB port. The PC

will instruct the user to apply one or more test pressures to the flow com-

puter or transmitter. For example, 0, 100 and 200 inH20. Squeeze the pump

to get close to the test pressure and use the vernier or fine pressure adjust

to dial in.

Static pressure calibration

will normally be applied to either the same

high pressure port of the flow computer or both the high and low pressure

ports. Refer to the manufacturer’s instructions for details. Connect the high

pressure sensor input (P2) to the appropriate port on the flow computer or

transmitter and to the high pressure test source. The PC will instruct the

pressures for the user to apply from the pressure source.

Temperature calibration

of the temperature measurement on the flow

computer is done with a single temperature point at the pipeline operating

temperature. Insert the RTD probe into the test thermowell and allow time

for the measurement to stabilize.

The PC will prompt the user to enter the temperature measured by the

calibrator. Remove the RTD from the test thermowell and the calibration is

complete.

Flow Computers with 4 to 20 mA inputs:

Many flow computers utilize a

low pressure, static and temperature transmitter to convert the measured

parameters into 4 to 20 mA signals. In this instance these transmitters may

need individual calibration if the test results are not satisfactory (see HART

Transmitter Calibration application note or video for more details). Anoth-

er source for errors in this configuration is the input A/D cards of the flow

computer. These can be independently tested using a mA signal source

from a loop calibrator.

STEP

1

STEP

2

STEP

3

STEP

4

To perform the test:

•

Always center the vernier

of your hand pump before

starting any pressure

calibration. This will allow

you to increase or decrease

the pressure when making

fine adjustments.

•

Store the temperature

probe in a protective

case such as the built in

slot of the 721 soft case.

Exposing the RTD probe

to mechanical stress can

reduce the measurement

accuracy of the probe.

• Be careful to not connect

the P1 low pressure

side of the calibrator

when doing high

pressure calibrations

or measurement or the

sensor will be damaged

and possibly rupture

creating a dangerous

condition.

•

Inserting the RTD probe

prior to the pressure

calibrations typically

allows sufficient time to

reach a stable temperature

measurement.

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

HART pressure and HART

smart RTD transmitter

754 videos

Custody Transfer calibration

application note

HART transmitter calibration

TECH

TIPS

35

Pressure Applications