138

810 Vibration Tester

Included Accessories

Tri-axial TEDS accelerometer, accelerometer

magnet mount, accelerometer mounting

pad kit with adhesive, accelerometer quick

disconnect cable, laser tachometer and

storage pouch, smart battery pack with cable

and adapters, shoulder strap, adjustable

hand strap, Viewer PC application software,

mini-USB to USB cable, getting started guide,

illustrated quick reference guide, users

manual CD-ROM, instructional training CD-

ROM, hard carrying case.

Ordering Information

Fluke 810 Vibration Tester

Diagnostic specifications

Standard faults

Unbalance, looseness, misalignment and bearing failures

Analysis for

Motors, fans, blowers, belts and chain drives, gearboxes, couplings, centrifugal pumps,

piston pumps, sliding vane pumps, propeller pumps, screw pumps, rotary thread/gear/

lobe pumps, piston compressors, centrifugal compressors, screw compressors, closed

coupled machines, spindles

Machine rotational

speed range

200 rpm to 12000 rpm

Diagnosis details

Plain-text diagnosis, fault severity (slight, moderate, serious, extreme), repair details,

cited peaks, spectra

Electrical specifications

Ranging

Automatic

A/D converter

4 channel, 24 bit

Usable bandwith

2 Hz to 20 kHz

Sampling

51.2 kHz

Digital signal

processing functions

Automatically configured anti-alias filter, high-pass filter, decimation, overlapping,

windowing, FFT, and averaging

Sampling rate

2.5 kHz to 50 kHz

Dynamic range

128 dB

Amplitude accuracy ±0.1 dBV

FFT resolution

800 lines

Spectral windows

Hanning

Frequency units

Hz, orders, cpm

Amplitude units

in/sec, mm/sec, VdB (US), VdB (Europe)

Non-volatile nemory SD micro memory card, 2 GB internal + user accessible slot for additional storage

Specifications

(Check the Fluke web for detailed specifications)

Battery type:

Lithium-ion, 14.8 V 2.55 Ah

Size (HxWxD):

186 x 267 x 70

Weight:

1.9 kg

Fluke 810

Language support:

eng, ger, fre, ita, spa, por

Warranty:

Three years on tester

One year on sensor and tachometer

The Fluke 810 Vibration Tester is the

most advanced troubleshooting tool

for mechanical maintenance teams

who need an answer now. The unique

diagnostic technology helps you quickly

identify and prioritize mechanical

problems, putting the expertise of a

vibration analyst in your hands.

Use the vibration tester to:

• Troubleshoot problem equipment and

understand the root cause of failure

• Survey equipment before and after

planned maintenance and confirm the

repair

• Commission new equipment and

ensure proper installation

• Provide quantifiable proof of equipment

condition and drive investment in

repair or replacement

• Prioritize and plan repair activities and

operate more efficiently

• Anticipate equipment failures before

they happen and take control of spare

parts inventories

• Train new or less-experienced

technicians and build confidence and

skill across the team

Features and benefits

• On-board identification and location of

the most common mechanical faults

(bearings, misalignment, unbalance,

looseness) focus maintenance efforts

on root cause, reducing unplanned

downtime

• Fault severity scale with four severity

levels help you prioritize maintenance

work

• Repair recommendations advise

technicians on corrective action

• On-board context sensitive help provide

real-time tips and guidance to new

users

• 2 GB expandable on-board memory

provide enough space for your

machinery’s data

• Self-test functions ensure optimal

performance and more time on the job

• Laser tachometer for accurate machine

running speed promotes confident

diagnoses

• Tri-axial accelerometer reduces

measurement time by 2/3 over single

axis accelerometers

• Viewer PC Software expands data

storage and tracking capacity

• Color LCD display and intuitive

multilingual, icon-based user interface

promote use right out of the box

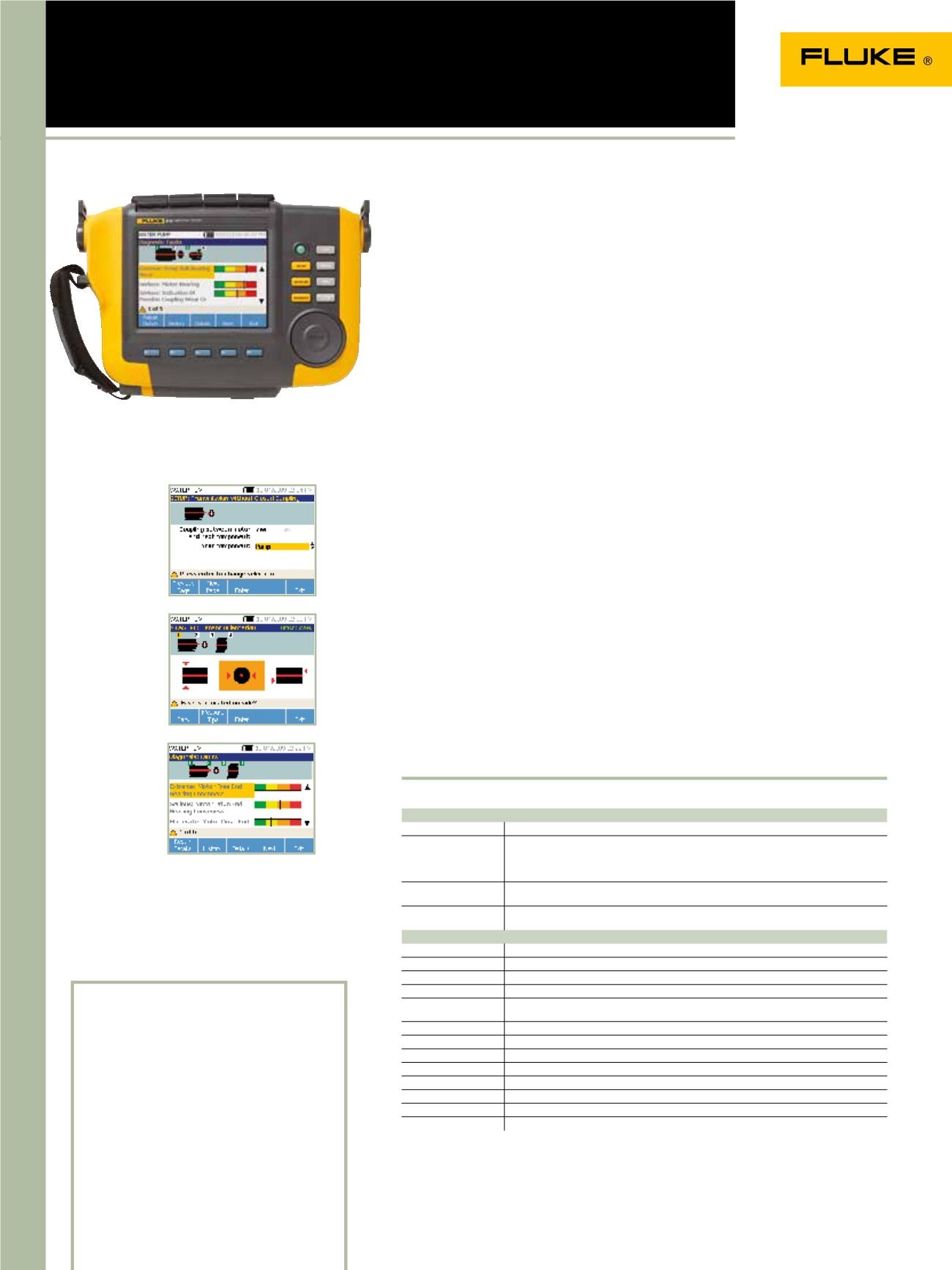

Motor diagnosis and repair in three simple steps

Set-up

Measure

Diagnose