134

What is “Intrinsically Safe”?

Intrinsically safe standards apply to all

equipment that can create one or more

of a range of defined potential explosion

sources:

• Electrical sparks

• Electrical arcs

• Flames

• Hot surfaces

• Static electricity

• Electromagnetic radiation

• Chemical reactions

• Mechanical impact

• Mechanical friction

• Compression ignition

• Acoustic energy

• Ionizing radiation

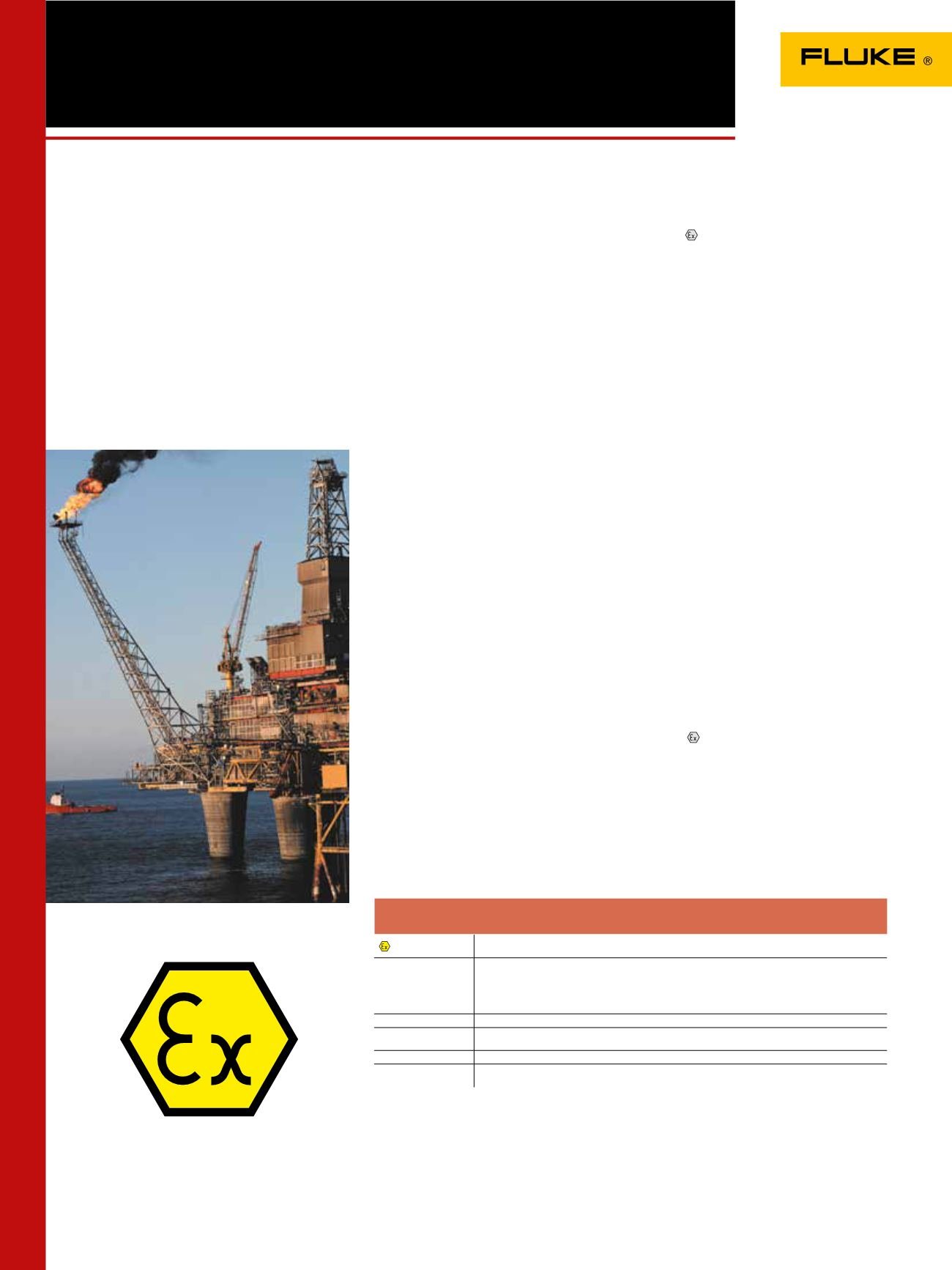

What industries are intrinsically

safe products designed for?

• Petro-chemical

• Oil platforms and refineries

• Pharmaceutical

• Bulk materials (e.g. grain)

• Mining

• Pipelines

• Any environment where explosive gases

are present

What is ATEX?

The primary intrinsically safe standard has

been set in the European Union with the

9/94/EC Directive, commonly called ATEX

(“Atmosphères Explosibles,” French for

explosive atmospheres). The stated goal of

the guidelines is to “help ensure the free

movement of products in the European

Union” by “minimizing the number of

safeguard clause applications, at least those

originating from divergent interpretations

The ATEX rules have been in place as a

voluntary standard since 1 March 1996.

The rules are mandatory on electrical

and electronic equipment for use in

environments subject to explosion hazard

sold in the EU starting 1 July 2003. From

this date onwards, all products sold for

use in explosive atmospheres must have

ATEX certification and carry the distinctive

symbol:

The Fluke Ex (IS) product line

Fluke is among the first manufacturers to

produce handheld test tools according to

the latest ATEX standards. The Fluke line of

intrinsically safe tools is designed to meet

the needs of technicians working in and

around hazardous areas:

• Install, maintain and troubleshoot

equipment by using the new Fluke 28 II Ex

Digital Multimeter

• Maintain and calibrate sensors,

transmitters and control loops with the

line of Ex field calibrators

The tools are ideal for environments

in petro-chemical plants, oil platforms,

refineries and other locations subject to risk

of explosion.

Apart from having the ATEX markings, the

visual difference between a standard Fluke

tool and the corresponding Ex version is

the different grey body colour and a red,

conductive holster designed specifically

to eliminate the potential for electrical

discharge.

Inside, the Fluke Ex tools have been

reengineered to reduce energy avoiding

generation of heat and electrical sparks.

They are premium products designed for

ultimate safety.

Making sense of ATEX certification

Fluke 707Ex is ATEX-compliant and is

certified II 2 G EEx ia IIC T4— but what

exactly does that mean?

Intrinsic safety is a protection standard

employed in potentially explosive

atmospheres. Devices that are certified

as “intrinsically safe” are designed to be

unable to release sufficient energy, by

either thermal or electrical means, to cause

ignition of flammable material (gas, dust/

particulates).

Here a brief explanation of the ATEX

certification designations.

A brief look at ATEX

The ATEX examination mark.This sign is required on all devices used in European hazardous

areas.

II 2 G

The classification of zones.

“II” designates the tool is approved for all non-mining areas.

“2” represents the category of the device, in this case the device is rated for the second most

hazardous areas.

“G” designates atmosphere, in this case gas, vapors and mist.

EEx

Explosion protection based on European Ex-regulations.

ia

The type of protection from explosion, in this case the energy in a device or connector has

been reduced to a safe value.

IIC

Gas Group. “IIC” indicates compatibility with the most dangerous gas group.

T4

Temperature class gives the user the maximum temperature of a surface that may be in

contact to the Ex atmosphere under fault conditions.T4 is rated at 135°C.

ATEX certification 707Ex