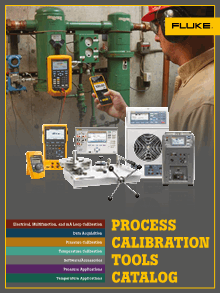

Suggested test tools

Calibrating a HART

smart pressure transmitter

Pressure transmitter manufacturers have improved the accuracy

and technology designed into these smart pressure measurement

devices. Many conventional calibration tools have become inad-

equate or simply unable to test and calibrate these high accuracy

pressure transmitters. Better test solutions are required.

Verifying and documenting the performance and adjusting

a HART smart pressure transmitter can require a bucket full of

tools. Performing this task with a HART enabled calibrator like

the Fluke 754 simplifies the task and reduces what you need

to carry.

Before going to the field:

install the pressure module adapter

to the hand pump with thread seal. Once the adapter is properly

installed on the pump, changing modules to different pressure

ranges is a snap, no tools required.

To get the accuracy needed:

to test these new high accuracy

transmitters match the pressure measurement standard range

closely to the device tested. For example, use a 100 psi

pressure module to calibrate and test a transmitter ranged at

100 psi. Industry standards suggest the measurement standard

should be 4-10 times more accurate than the device being tested

so best-in-class accuracy is required.

The Fluke 754 utilizes the 750P series pressure modules and

has built-in HART functionality to enable smart trims on trans-

mitters. It can also document transmitter performance before and

after adjustment and calculate pass/fail errors.

Fluke 754 Docu-

menting Process

Calibrator-HART

See pg 5

Fluke 750P Series

Pressure Modules

See pg 12

Fluke 700G

Precision Pressure

Gauge Calibrator

See pg 13

Fluke 700PTP-1

Pneumatic Test Pump

See pg 23

26

Pressure Applications