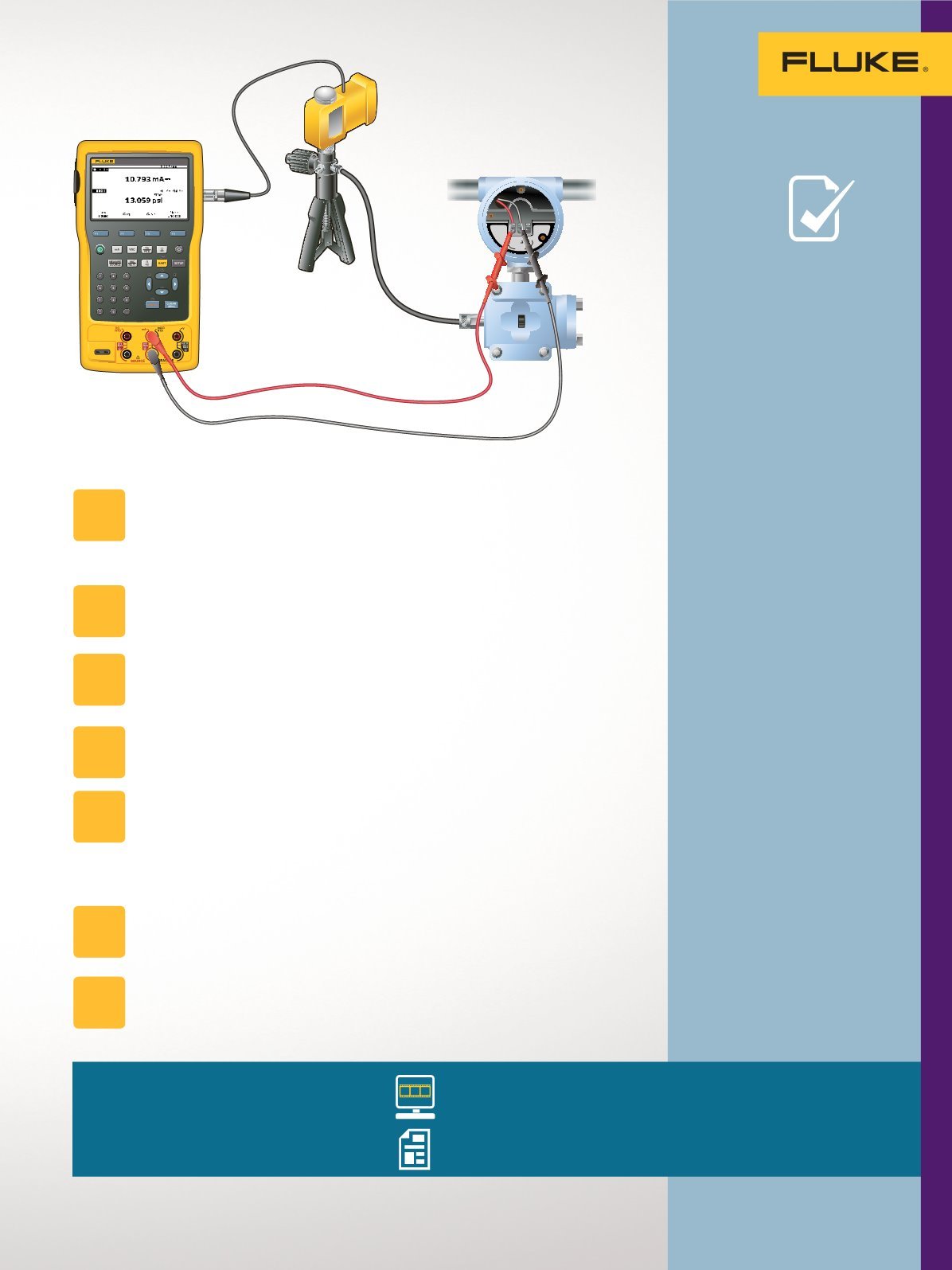

Hand

Pump

Pressure Input

mA Measure, 24V Loop

Pressure

Module

754

DOCUMENTINGPROCESSCALIBRATOR

+ – –

TEST

PWR/

COMM

Sometimes it is necessary to trim

the input sensor of the transmit-

ter more than once. It is critical

that the pressure module be ze-

roed before test and adjustment.

For best ßadjustment success:

•

After pressing Fetch for

the pressure measurement,

select the trim button quickly

before the pressure measure-

ment changes.

•

Give the measured

mA

and

pressure time to settle for best

measurement results.

•

Always de-bug the pressure

test setup for leaks in the

shop before going to the

field, including installing the

pressure module connection

adapter to the hand pump.

•

If the full scale value of the

transmitter is less than 25 %

of the full scale of the pres-

sure module, select a lower

range pressure module for

best results.

•

If performing higher

pressure calibrations with a

hydraulic pump, use the cor-

rect fluid such as mineral oil

or de-ionized water. Standard

tap water will leave deposits

in the pump and cause

erratic operation, leaks or

difficulty priming.

•

If the pass/fail accuracy is set

at the limits for the transmit-

ter, adjust the transmitter if

the errors are greater than

25 % of limits.

•

If the errors are less than

25 % of limits, it might be best

to not adjust the transmitter

as adjusting might make it

less accurate.

Isolate the transmitter from the process being measured and its loop

wiring. If measuring the mA signal across the transmitter test diode

leave the wires intact, but note this method does not give the best mA

measurement accuracy.

Connect the mA measurement jacks of the 754 to the transmitter.

Connect the pressure module cable to the 754 and connect the

transmitter test hose from the hand pump to the transmitter.

Press the HART button on the calibrator to see the configuration of

the transmitter.

Press HART again and the calibrator will offer the correct measure/source

combination for the test. If documenting the calibration press As-Found,

input the test tolerance and follow the prompts. If the measured mA signal

at the test points is found within tolerance the test is complete. If not,

adjustment is required.

Select adjust and trim the transmitter’s pressure zero, mA output signal

and input sensor.

After adjustment select As-Left, document the condition of the transmitter

after adjustment and if the test passes, it is complete.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

5

STEP

6

STEP

7

To perform the test:

Additional resources

For more in depth information about

this application check out these videos

and application notes from Fluke.

See the smart pressure calibration video at:

www.fluke.com/pressurevideoHART Smart Transmitter calibration application note at:

www.fluke.com/smarttranappnoteTECH

TIPS

27

Pressure Applications