PROCESSMETER

789

%STEP COARSE FINE

SpanCheck

mA

mA

mA

mA

mV

V

V

A

OUTPUT

LOOPPOWER

250

HART

OFF

mA

SOURCE

OUTPUT 0-24mA

SIMULATE

A

COM

V

MINMAX

100

%

0

%

HOLD

REL

Hz

RANGE

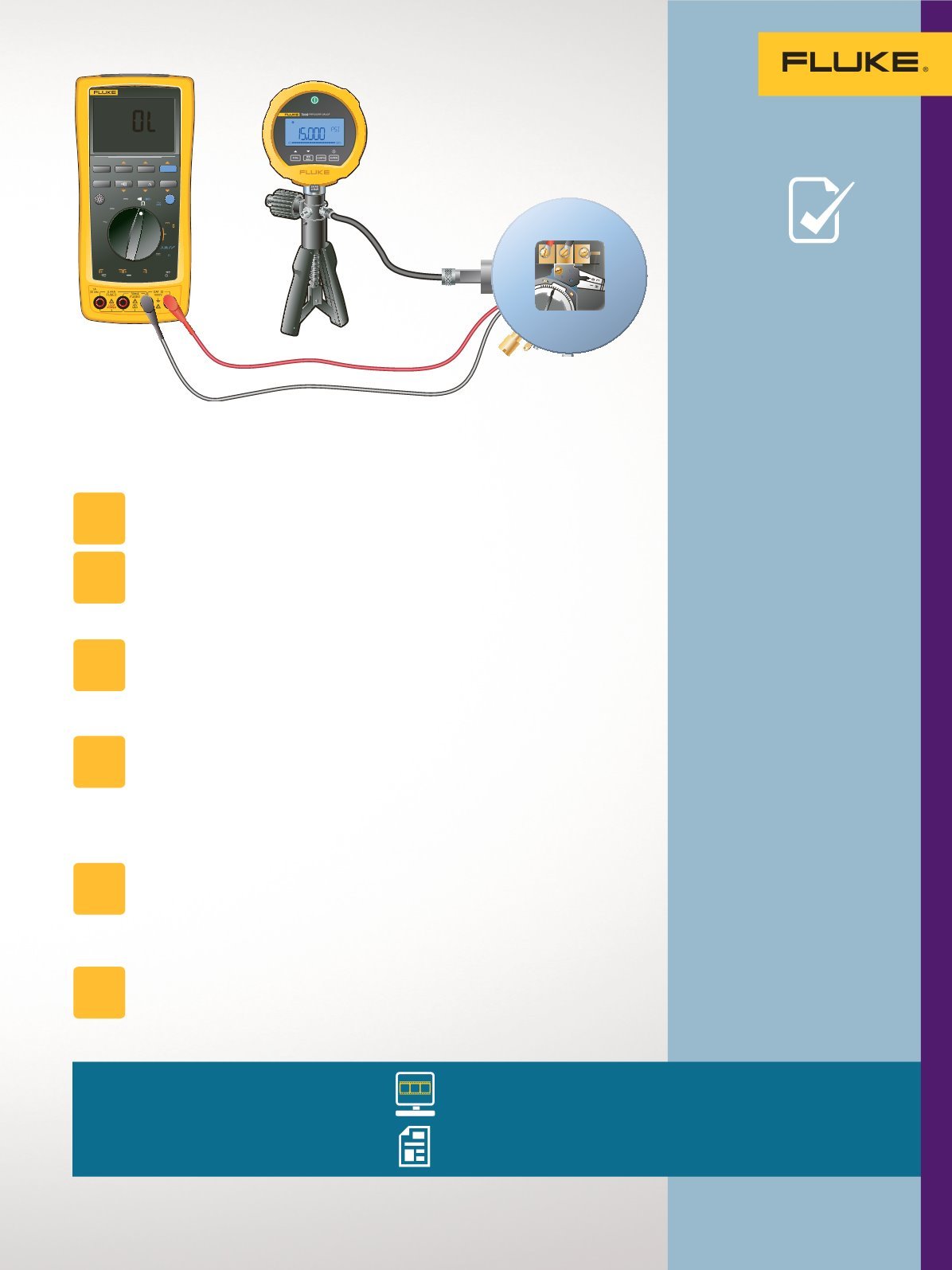

Hand

Pump

Pressure

Gauge

Pressure Input

When you use a Fluke 754

or 3130 to automate the

pressure switch calibration,

vary the applied pressure

slowly, back and forth across

the setpoint and reset points.

The display will make it

apparent that the set/reset

has changed and the actuals

will be logged.

Safely disconnect the device from the process it controls.

Connect the calibrator or DMM to the common and NO (normally open)

output terminals of the switch. The DMM or calibrator will measure an

“open circuit”. if measuring continuity. If measuring V ac be sure the tool is

properly rated for the voltage being measured.

Connect the pressure switch to a pressure source such as a hand pump

connected to a gauge.

Increase the source pressure to the setpoint of the switch until the switch

changes state from open to close. Manually record the pressure value

when the DMM indicates a “short circuit” or if using a calibrator it will

record the value for you.

Continue to increase the pressure until the maximum rated pressure.

Slowly reduce the pressure until the switch changes state again, and

resets from closed to open, then record the pressure.

The setpoint pressure was recorded when the pressure was rising.

The deadband value is the difference between the rising setpoint

pressure and the falling pressure reset point.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

6

To perform the test:

Setup

Rising pressure

Falling pressure

Calculation

Additional resources

For more in depth information about

this application check out these videos

and application notes from Fluke.

See the pressure switch test video at:

www.fluke.com/pressureswitchCalibrating pressure switches with a DPC

TECH

TIPS

STEP

5

31

Pressure Applications