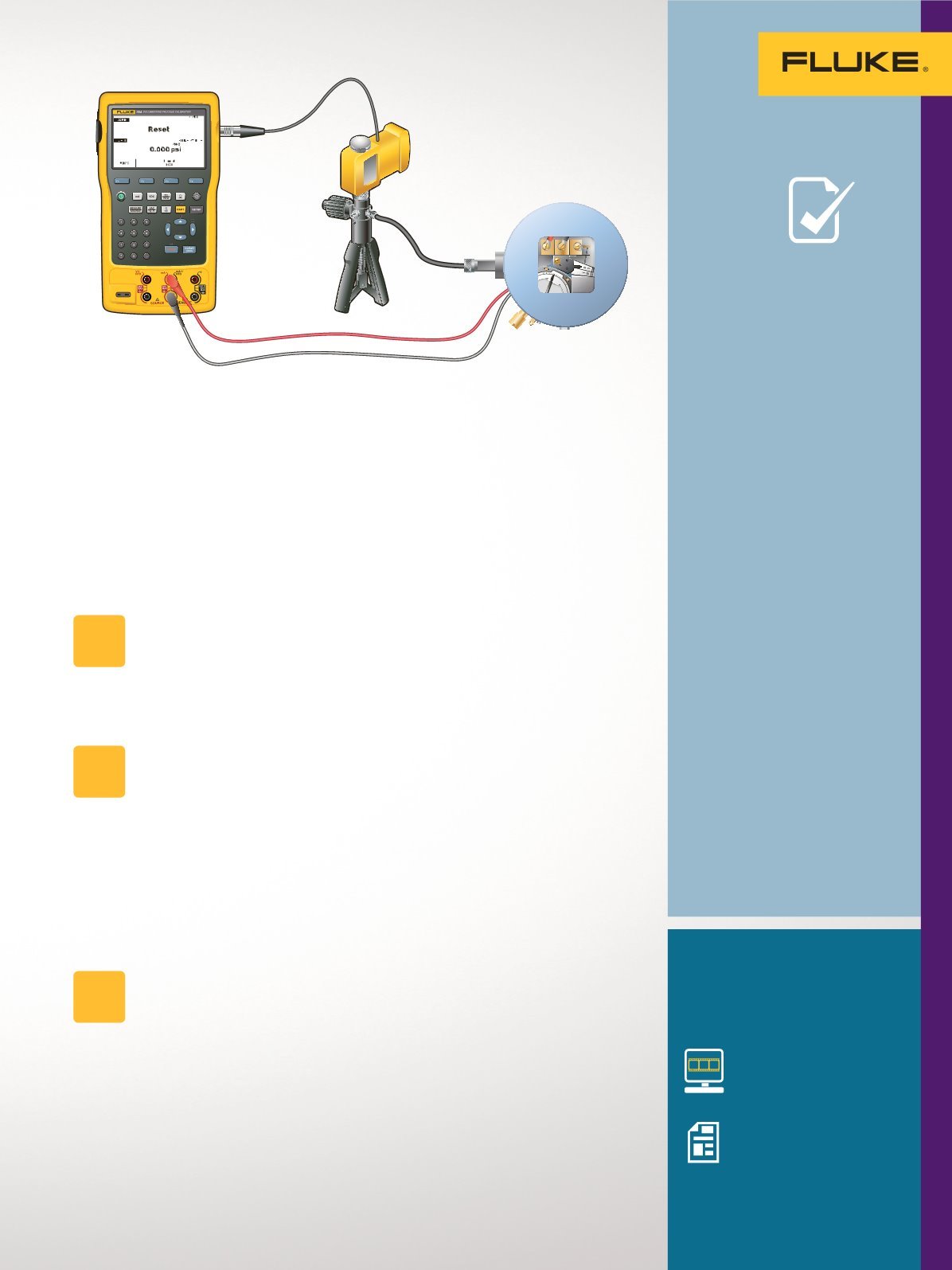

Hand

Pump

Pressure

Module

Pressure Input

•

The key to a good switch

test is repeatability.

Repeatability is best

achieved by applying a

slow change in pressure to

the switch as it approaches

its set or reset pressure.

•

When performing the test

find out where the switch

sets and make sure the

vernier/fine adjustment of

your test pump has enough

adjustment to vary the

pressure up to the set point.

In this way the pressure

can be changed slowly

capturing an accurate

switch set point pressure.

Repeat this procedure for

the reset point.

•

With practice you can get

the vernier of the pump

within range of the set and

reset point pressure and

get excellent repeatability

of your tests (within the

limitations of the switch

being tested).

TECH

TIPS

To get started testing the switch, connect as shown above. In this example

we will test dry contacts and continuity. To measure continuity for the test

select resistance measurement. Then toggle to the source screen mode

and select pressure to display the pressure generated by the hand pump

and measured by the pressure module. Advance the calibrator mode to the

split screen test mode.

The next step is to describe the switch and whether it is normally open

or closed at ambient pressure. The relaxed state of the switch is the

reset state. The set state is the condition of the switch it changes to with

applied pressure or vacuum. In this example the switch is normally open

and is expected to close when the pressure applied exceeds 10 psi. Next

the allowable pressure variance of the switch set state and deadband size

needs to be defined. In this example the ideal switch set value is

10 psi and is allowed +/- 1 psi of deviation. The allowable reset pressure

is described in the deadband tolerance. In this instance the reset state

must be more than 1 psi less than the found set pressure but not greater

than 3 psi less than the found set pressure.

Once the test tolerances are fully defined start the test. Increase the

pressure until the calibrator captures the set state pressure value. Then

decrease the pressure until the reset pressure is found. Repeat increasing

and decreasing the pressure across the switch looking for repeatability in

your set and reset pressure measurements. Once satisfied with the result

press done to get the pass/fail evaluation of the switch. If the switch fails

the test adjustment or replacement of the switch may be required. If the

switch is adjusted repeat the test to document the As-Left condition of the

switch before putting back into service. The test result is now documented

and ready for upload to calibration management software.

To perform the test:

With a modern documenting calibrator you can test for dry contacts opening and

closing on the switch or if you are using the Fluke 753 or 754 you can leave the

switch connected to the live voltage and the calibrator will measure the changing

AC voltage and interpret it as opening and closing of the switch.

One cautionary note: it is always safer to test a de-energized circuit, but this is not

always possible. Also, do not measure AC voltages above 300 V ac as that is the

maximum rating of the 75X family. 480 V ac 3-phase voltages must be de-energized

and disconnected from the switch if testing with the 75X family.

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

Pressure switch video

Pressure switch

application note

Pressure calibration

application note

STEP

1

STEP

2

STEP

3

33

Pressure Applications