•

Dry-wells have inserts

that are interchangeable

and have a variety of hole

patterns to accommodate

various probe sizes.

•

To achieve published

performance levels, the

insert’s hole size should

be no more than a few

hundredths of an inch

larger than the probe being

calibrated.

•

Avoid placing fluids in

a dry-well. If fluids are

required, use a Micro-Bath

instead.

•

If climbing a ladder is

required, dry-wells are

safer than baths, and

handheld dry-wells may be

the most convenient.

TECH

TIPS

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

How to Calibrate an RTD

Using a Dryblock Calibrator

webinar

914X Field Metrology Wells

Video Series

Industrial Temperature

Calibrators Workload Matrix

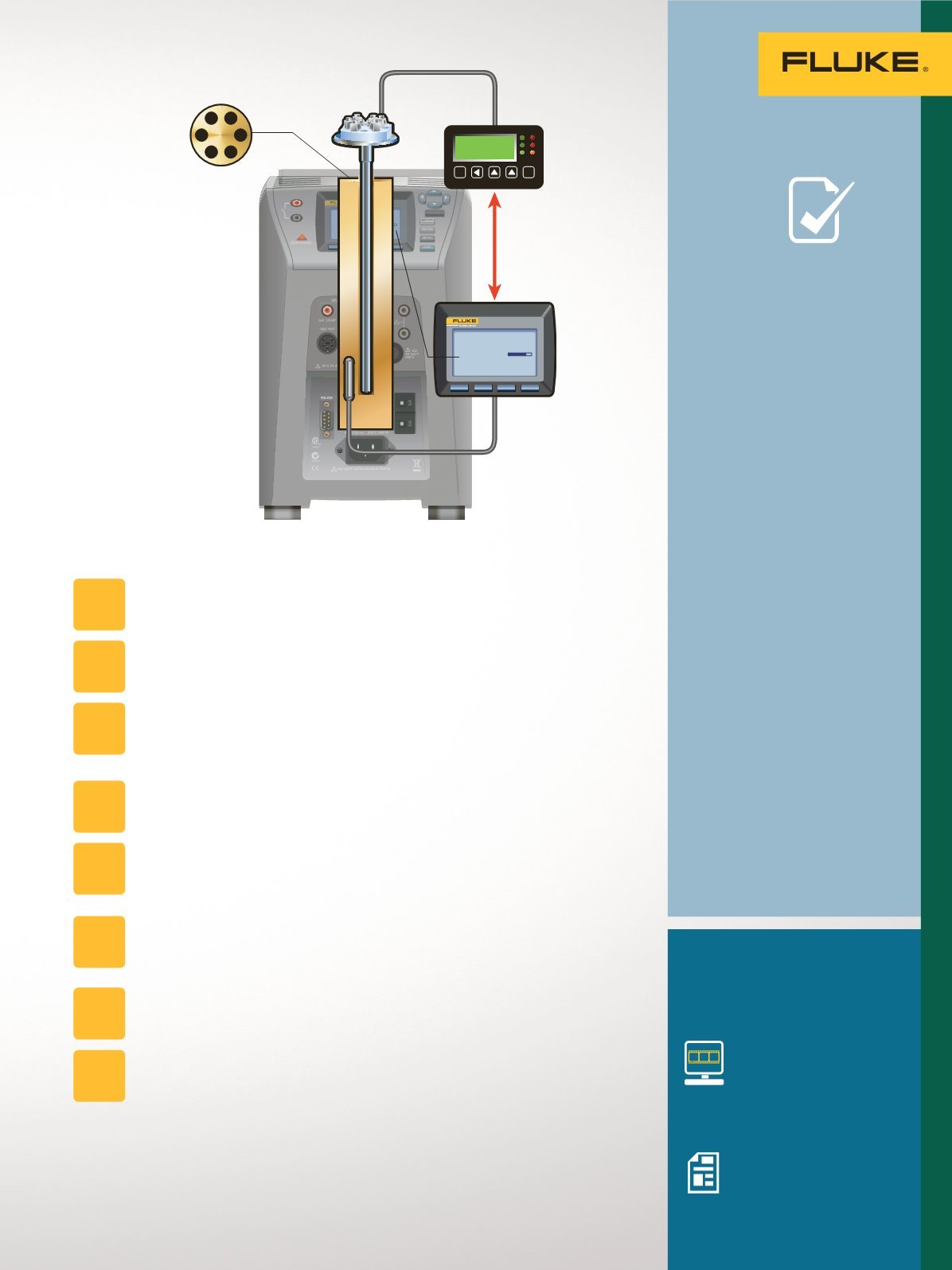

To perform the test:

Isolate the sensor from the process.

Fully immerse the sensor into a precision temperature source, such as a

dry-well or bath capable of covering the required temperature range.

For best accuracy, also fully immerse a temperature standard into the dry-

well or bath for comparison (the process version of Field MetrologyWells

have a built-in precision readout for the temperature standard).

To check the calibration of the RTD separately from the control system

temperature indicator, disconnect the RTD from the electronics.

Connect the RTD to a precision instrument capable of measuring resis-

tance. (The process version of Field MetrologyWells have the required

electronics built in.)

Adjust the temperature of the bath or dry-well to each of the test points

(With Field MetrologyWells these test points can be preprogrammed and

automated.)

At each test point record the readings of the temperature standard and

RTD.

If measuring the RTD separate from its measurement electronics, compare

the measured resistances to the expected resistance from the applicable

temperature table. Otherwise, compare the reading on the instrument display

to the reading of the temperature standard (which may be the dry-well).

STEP

1

STEP

2

STEP

3

STEP

4

STEP

6

STEP

8

STEP

7

STEP

5

F4

F3

F2

F1

100.00°

C

F4

F3

F2

F1

100.00°

C

ENTER

MENU

100.2° C

47

Temperature Applications