TESTDCPWR

++–

–

754

DOCUMENTINGPROCESSCALIBRATOR

TESTDCPWR

++–

–

C-2

C-1

S-3

S-2

S-4

S-1

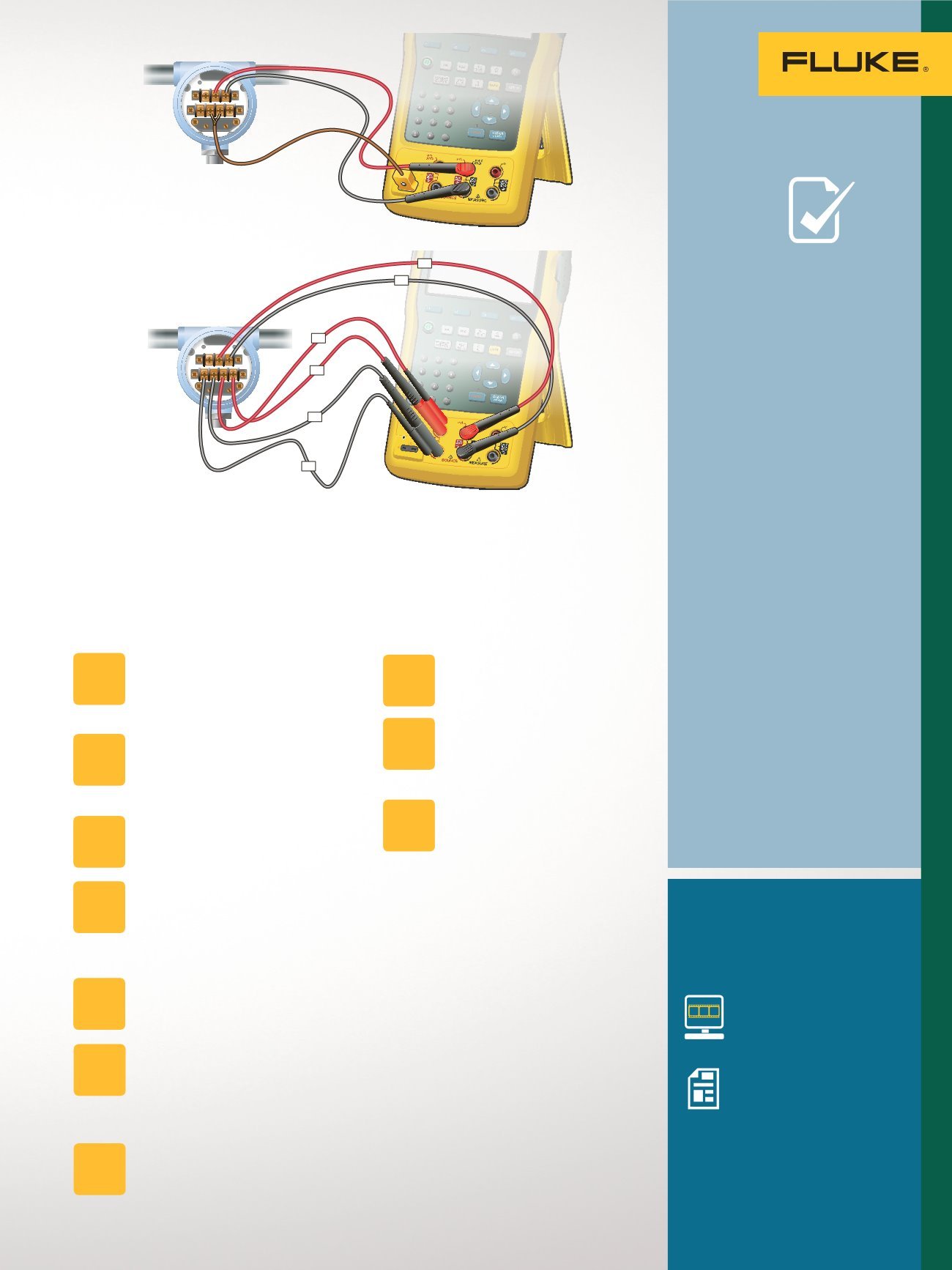

TC transmitter calibration connection

©2015 Fluke Corporation. Specifications subject to change without notice. 07/2015 6005865a-en

RTD transmitter calibration connection

TESTDCPWR

++–

–

754

DOCUMENTINGPROCESSCALIBRATOR

TESTDCPWR

++–

–

C-2

C-1

S-3

S-2

S-4

S-1

TC transmitter calibration connection

©2015 Fluke Corporation. Specifications subject to change without notice. 07/2015 6005865a-en

RTD transmitter calibration connection

51

•

When simulating a thermo-

couple signal from a simu-

lator, always use the correct

thermocouple wire for the

test, either the exact same

TC wire type or a compati-

ble extension wire type.

•

When simulating tempera-

ture using a calibrator with

active reference junction

compensation, remember

the calibrator actively

compensates for tempera-

ture changes. Changes

in ambient temperature

should be compensated

for automatically.

•

When testing 3-wire RTD

circuits make sure to con-

nect all three wires from

the sourcing RTD simulator

to the device being tested.

Shorting out the compensa-

tion wire at the transmitter

defeats the lead compensa-

tion circuit and introduces

measurement errors.

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

Testing, troubleshooting,

calibrating process

temperature devices

webinar

Temperature calibration

application note

Fluke temperature

calibrators deliver

high accuracy, speed,

and convenience

TECH

TIPS

Connect the calibrator to the

device input as shown in

figure B.

Connect the calibrator output

with the right combination

to match the device

configuration (2, 3 or 4-wire).

Use the test procedure at left

for thermocouple testing,

starting at step 3.

Disconnect the process

measurement sensor and

connect the test connection

wires in its place (Figure A).

Connect the mini-connector

from the test wires to the TC

source connection of the cali-

brator.

Connect a DMM or other mea-

surement tool to the tested

device’s mA output.

Verify the devices range or span.

Apply the 0% value with the

simulator and verifywith the

DMM that the output mA value

or voltage is as expected.

Repeat the test, applying the

50% and 100% temperature

signals.

If the measured output of the

device is within limits, the test

is complete. If not, adjust the

device at zero (offset, 0%) and

span (gain, 100%).

Repeat steps 4 and 5 and verify

for a correct response.

To use a thermocouple

simulator to test a device

with a thermocouple input:

STEP

1

STEP

1

STEP

2

STEP

3

STEP

2

STEP

3

STEP

4

STEP

5

STEP

6

STEP

7

To perform the test:

To use an RTD simulator

to test a device with an

RTD input:

51

Temperature Applications