SAVE

NEXT

HOME

LOG

RESET

ENTER

RECALL

HOLD

STATS

°

C

°

F

SETUP

TREND

mV

RS

232

12

VDC

30

VMAX

T1

T2

1524

CALIBRATION

THERMOMETER

READOUT

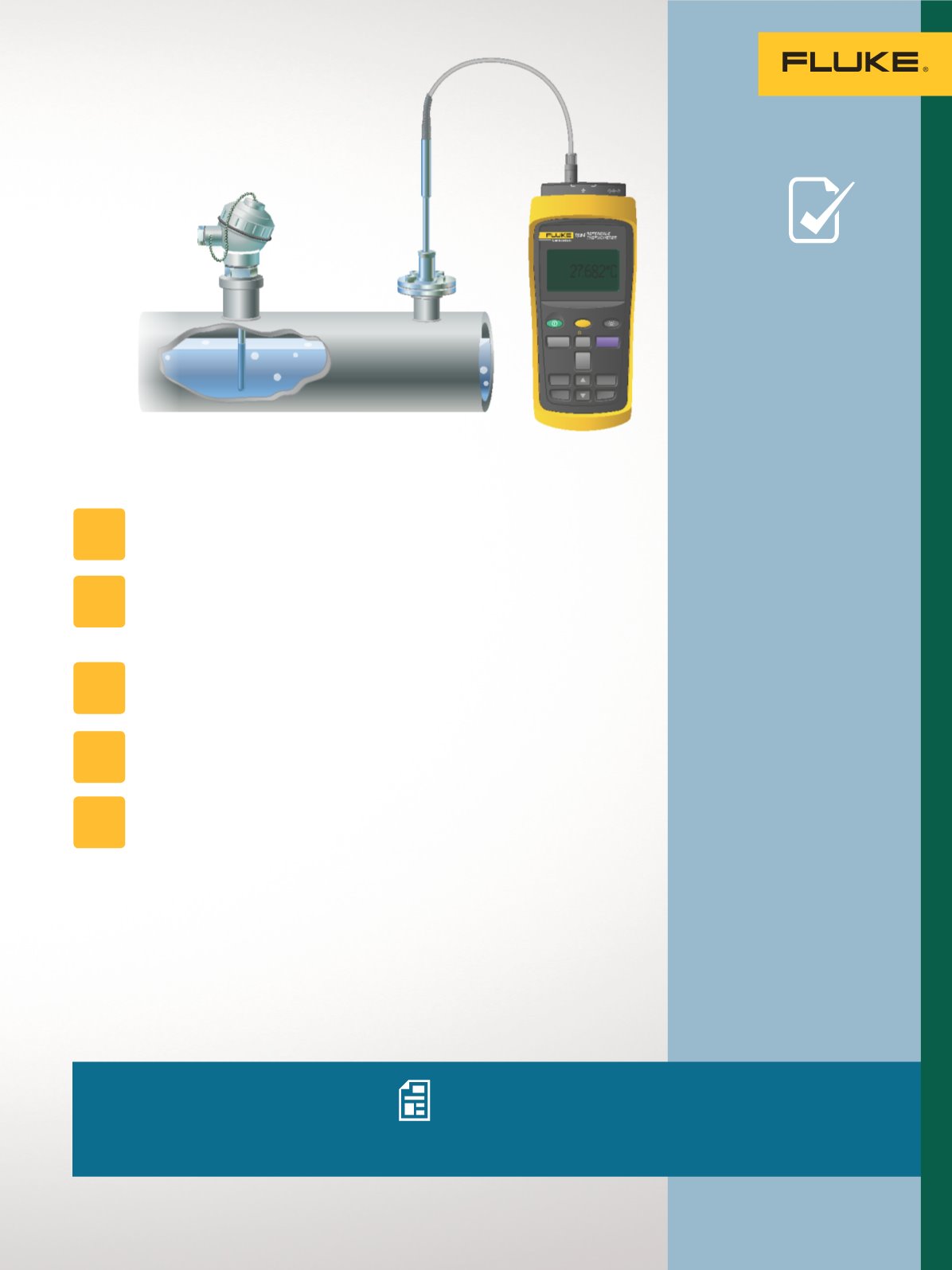

The test well (thermowell) should be within a few inches of the

temperature transmitter and sensor assembly to be tested.

Make sure that the probe of the temperature standard is long

enough to reach the bottom of the test well and that air gaps

between the probe and well are minimized.

Wait for the temperature standard to reach the temperature of

the test well. This will take a few minutes.

Check for temperature stability. A graphing digital thermometer

such as the 1524 makes stability easier to recognize.

Record the reading from the measurement system and the

temperature standard to determine whether the measurement

system’s readings are suspect.

•

For this type of application

a battery powered digital

thermometer is usually

preferred.

•

A graphing display helps

the technician visualize

trends such as stability

quickly and easily.

•

Ensure that both the probe

and the readout of your

temperature standard

have traceable calibration

certificates from a

competent laboratory.

•

If the probe and readout

separate from each other,

smart connectors, which

include probe calibration

constants, provide a

best practice method of

ensuring that the readout

is using the correct

probe calibration in its

temperature readings.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

5

To perform the test:

Additional resources

For more in depth information about

this application check out these videos

and application notes from Fluke.

Temperature measurement and calibration:

What every instrument technician should know

Industrial temperature readout and probe

selection guide

Process Calibration Tools: Temperature Applications

TECH

TIPS

53

Temperature Applications