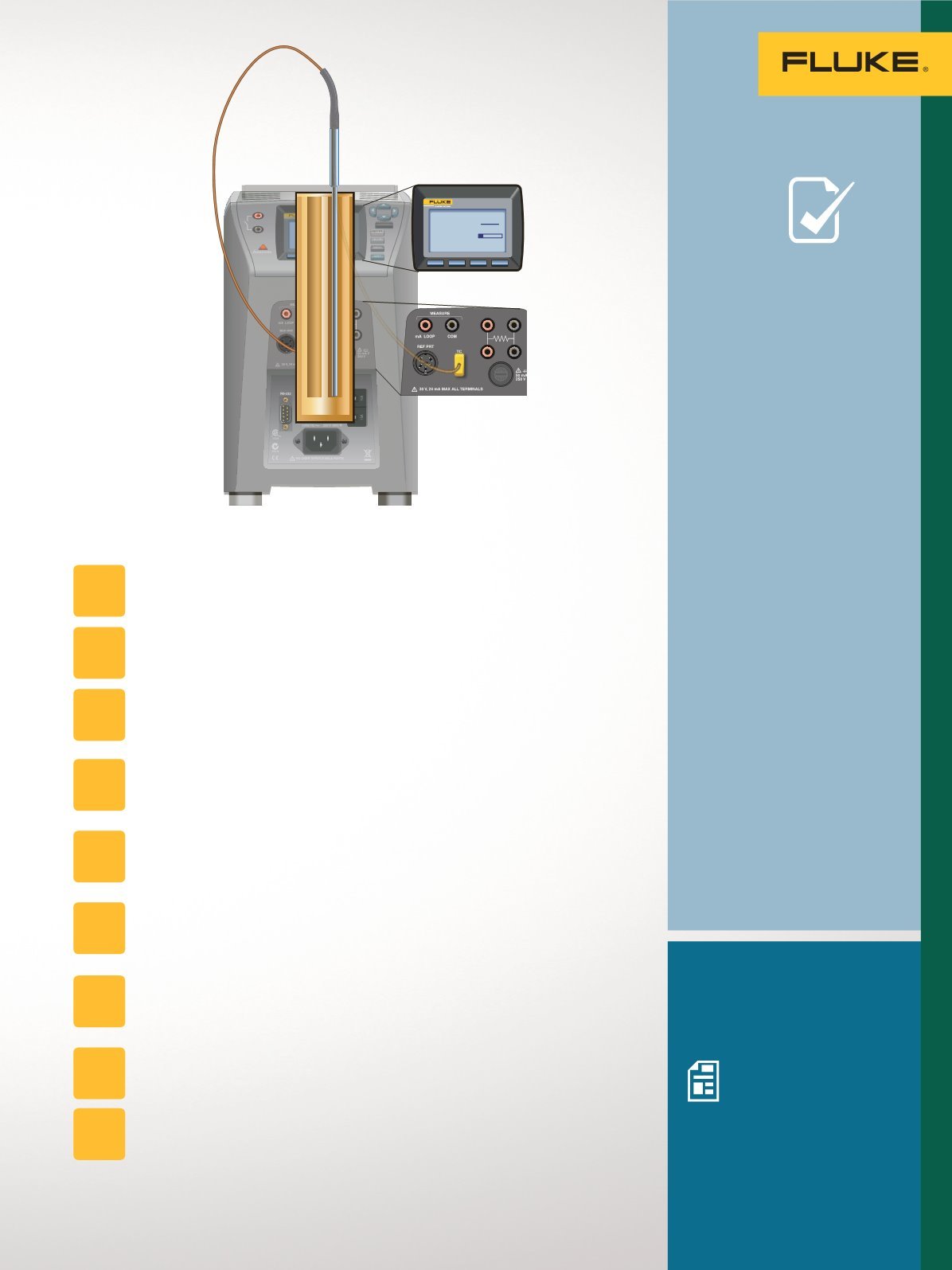

F4

F3

F2

F1

100.00°

C

F4

F3

F2

F1

266.03°

C

SETPT: 266.00 °C

TC—T : 265.783

°

C

HEAT: 22

•

/

•

•

Depending on the

thermocouple, incorrectly

setting reference junction

compensation may result

in a temperature error

of around 23 °C. Also,

the reference junction

compensation accuracy

of the meter may be the

largest contributor to

the error.

•

Thermocouple wire

generates a voltage

whenever two adjacent

points along the wire are at

different temperatures.

•

The whole length of the

wire (not just the probe

tip) generates the voltage.

This means the whole

wire needs to be treated

carefully and considered

during the calibration.

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

Thermocouple

Fundamentals

application note

TECH

TIPS

To perform the test:

Isolate the sensor from the process.

Fully immerse the sensor into a precision temperature source such as a

dry-well or bath capable of covering the required temperature range.

To check the calibration of the thermocouple separately from control

system temperature indicator, disconnect the thermocouple from

the electronics.

Connect the thermocouple to a precision instrument capable of measuring

millivolts. (The process version of Field MetrologyWells have the required

electronics built in.)

If the thermocouple has a reference junction (most do not), then ensure

that the reference junction is also immersed at the required reference

temperature. Usually, this is 0 °C.

Typically, the thermocouple will not have a reference junction. In that

case, ensure that the precision voltage measurement device has reference

junction compensation (may be identified as RJC or CJC) turned on.

Adjust the temperature of the bath or dry-well to each of the test points.

(With Field MetrologyWells these test points can be preprogrammed

and automated.)

At each test point record the readings of the temperature standard and

thermocouple.

If measuring the thermocouple separate from its measurement electronics,

compare the measured voltage to the expected voltage from the applicable

temperature table. Otherwise, compare the reading on the instrument display

to the reading of the temperature standard (which may be the dry-well).

STEP

1

STEP

2

STEP

3

STEP

4

STEP

6

STEP

8

STEP

9

STEP

7

STEP

5

49

Temperature Applications