Additional resources

For more in depth information about

this application check out these videos

and application notes from Fluke.

Emissivity makes a difference

How to Calibrate an IR Thermometer

webinar

Infrared Temperature Calibration 101

application note

Infrared Thermometer Calibration – A Complete Guide

•

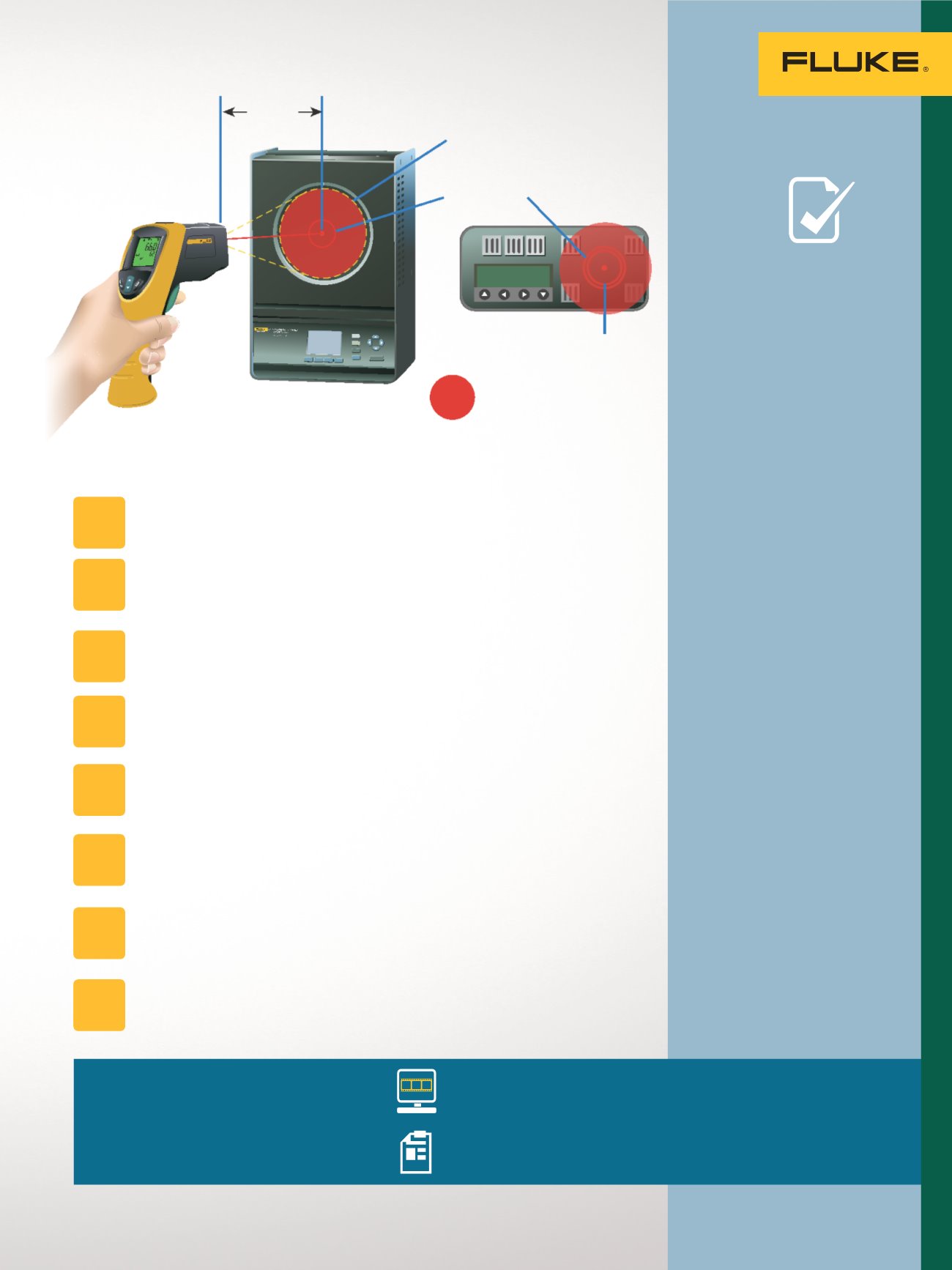

Emissivity makes a big

difference in infrared

temperature measurement.

•

The temperature and

emissivity of the 4180

and 4181 are calibrated

radiometrically for the

most reliable and

traceable results.

•

The Fluke 4180 and 4181

can be set to match the

emissivity setting of fixed

emissivity thermometers.

•

The large area of the 4180

and 4181 target allows

infrared thermometers

to be calibrated at the

recommended distance

without including

unwanted surfaces in the

field of view.

•

Use a mounting device such

as a tripod to maintain the

calibration distance.

•

Measure the calibration

distance from the flat plate

surface to the surface of

the front housing of the

infrared thermometer.

TECH

TIPS

To perform the test:

Allow at least 15 minutes for the IR thermometer to reach the

temperature of the shop or laboratory.

Set the radiation source to the desired calibration temperature.

Depending on the temperature range a low, high, and midpoint

temperature may be chosen.

If the infrared thermometer has an emissivity setting, it should be set to

match the calibrated emissivity of the source.

Position the infrared thermometer at the manufacturer’s recommended

calibration distance.

Center the infrared thermometer on the calibrator surface. Do this by

adjusting the aim slightly side to side and up and down to maximize

the signal.

The measurement time should be ten times longer than the infrared

thermometer’s response time. This is typically five seconds for Fluke

infrared thermometers.

Record the calibrator indicated reading and the indicated reading of

the thermometer under test to determine the error and tolerance status

of the thermometer at each set point.

Repeat for the other set point temperatures.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

6

STEP

8

STEP

7

STEP

5

= IR thermometer field of view

Smaller target

Manufacturer

recommended

large target

IR thermometer

spot size

1 9 9 . 3

d

Measuring

(d) distance

561HVACPro

IRTHERMOMETER

61

Temperature Applications