•

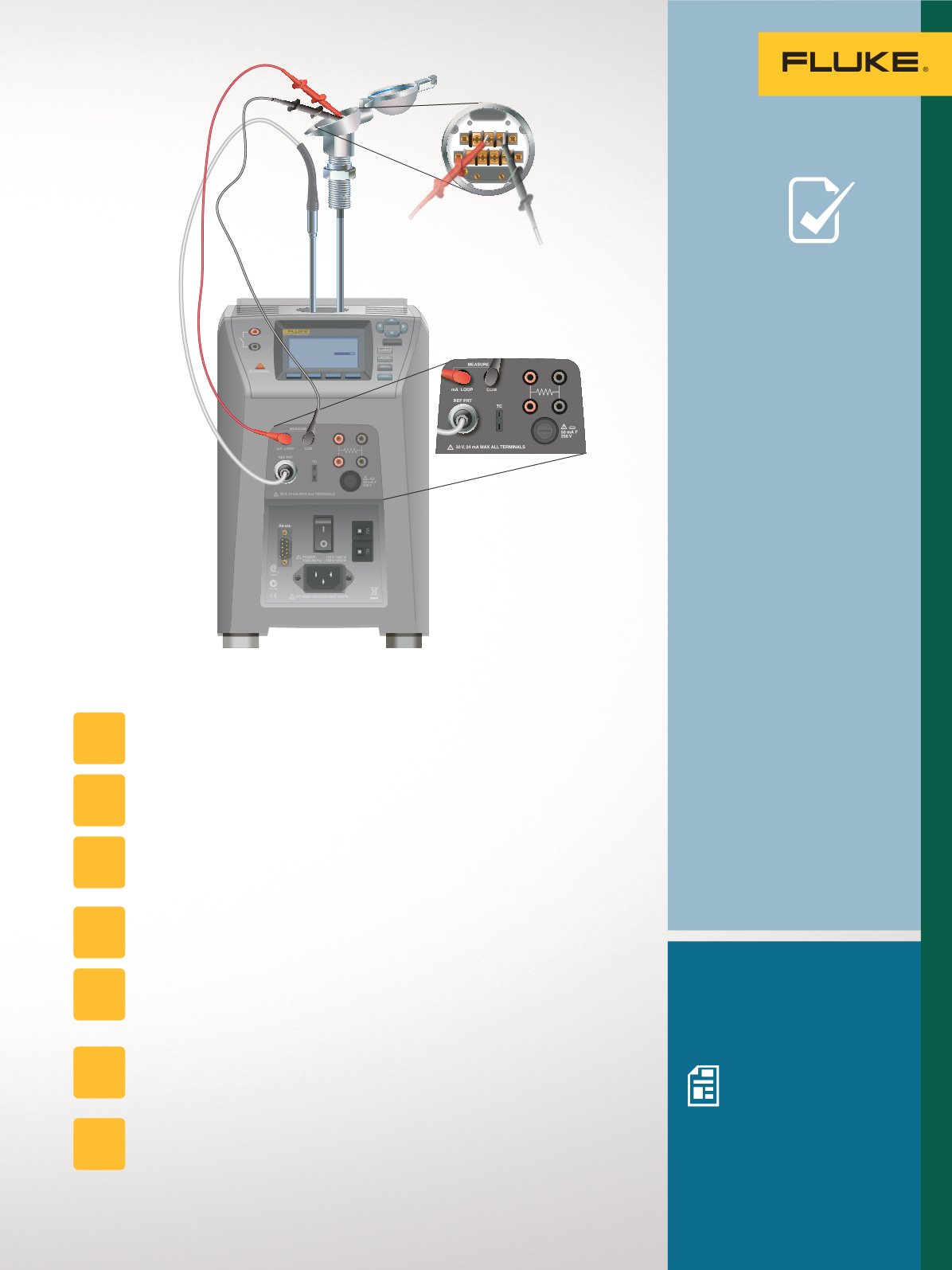

Streamline the process with

automation and provide

documentation using a

Fluke 754.

•

Seventy-five percent of

the errors in a temperature

measurement system comes

from the sensor.

•

At minimum, you need a

calibrator, and a device

to measure 4-20 mA and

power the loop.

•

Choose a temperature

standard with a 90 degree

angle bend to ensure both

the temperature standard

and the transmitter fit in

the dry-well at the

same time.

Additional resources

For more in depth information

about this application check out

these videos and application notes

from Fluke.

TECH

TIPS

To perform the test:

Isolate the sensor from the process.

Fully immerse the sensor into a precision temperature source such as a

dry-well or bath capable of covering the required temperature range.

Connect the temperature standard and 4-20 mA output of the

transmitter to a suitable meter or calibrator (for example, the process elec-

tronics on a Fluke Field MetrologyWell or the inputs of a Fluke 754).

Power the loop. (The Fluke 754 and the process electronics in a

Field MetrologyWell have this capability.)

Adjust the temperature of the bath or dry-well to each of the test points.

(With Field MetrologyWells, these test points can be preprogrammed

and automated.)

At each test point, monitor and record the readings of the

temperature standard and the local or remote readings connected

to the transmitter output.

Also, record the 4-20 mA output of the transmitter to determine which

device needs adjustment if an adjustment is required.

STEP

1

STEP

2

STEP

3

STEP

4

STEP

6

STEP

7

STEP

5

Eliminating Sensor

Errors in Loop Calibrations

Multifunction calibration

using the 7526A Precision

Process Calibrator

Improving loop calibration

temperature accuracy

F4

F3

F2

F1

100.00°

C

TESTDCPWR

++–

–

63

Temperature Applications